One of Our More Extensive Case Studies

Why We Were Called in

GoSafety was brought in as the clients company had spent over a hundred thousand dollars developing a health and safety system and training staff over the previous twelve months on multiple sites, however the health and safety systems were still not embedded in the business, a high number of high risk activities were still occurring on a regular basis. There was a low near hit, incident and hazard reporting rate.

The challenge

Embed health and safety systems into the business by training and upskilling managers to ensure they clearly know they are ultimately responsible for health and safety in their work areas, so they knew Health and safety was a big part of their job – Not the safety coordinators responsibility

Embed health and safety awareness with all staff to focus on proactive lead indicators ie; report hazards, Near Hits, Incidents and to empower them to plan and manage high risk activities adhering to new Zealand health and safety legislation and eliminate high risk taking.

This would benefit the company by;

- Reducing the risk of a serious incident on multiple sites

- Raise the level of safety awareness with all staff

- Raise the standard of safety behaviours in all staff

- Reinforce safety expectations, We do not expect any one on any site to take high levels of risks (staff, Visitors and contractors)

- To get all to discuss safety on a daily basis (The good and bad)

- Empower staff to educate contractors on our standards

- Have a new standard of “This is how we roll around here”

What we Did

Visited all sites to carry out audits, inspections, spent time to mentor, coach managers/ staff and to discuss and have their input on system options

Developed and rolled out a four hour interactive health and safety awareness programme to groups of 5 to ten staff at a time, all staff members in the business attended a training session over a two month period, staff and managers attended separate sessions as some of the messages were aimed at different levels. The messages were stating the new way things will be done including placing a line in the sand making it clear unsafe acts were not tolerated. All of the below initiatives were rolled out during the safety awareness presentation

- Developed and rolled out weekly toolbox meetings for all sites

- Developed Monthly safety themes to standardise information disseminated though out the business and ensure at risk topics were discussed at all toolbox meetings, At home topics were all so discussed to remind employees to think about safety in everything they do.

- Developed and implemented H&S Mandatory safety rules throughout the whole company and placed a line in the sand during the awareness training.

- Developed, trained and Implement a Managers safety observations process

- Trained managers to have discussions with workers and document the discussions

- Developed a ProPad for all staff to carry for reporting Near Hits, Hazards, Incidents, Idea’s, SBO’s etc..

- Developed robust General and site Hazard registers to discuss and review at the H&S committee meetings

- Started discussing health and safety issues on a day to day basis – as ‘part of the culture

- Developed and implemented a rehabilitation process for work related and off work related incidents

Example of the carbon copy Pro Pad book that was small enough to fit in an overall pocket

Example of the carbon copy Pro Pad book that was small enough to fit in an overall pocket

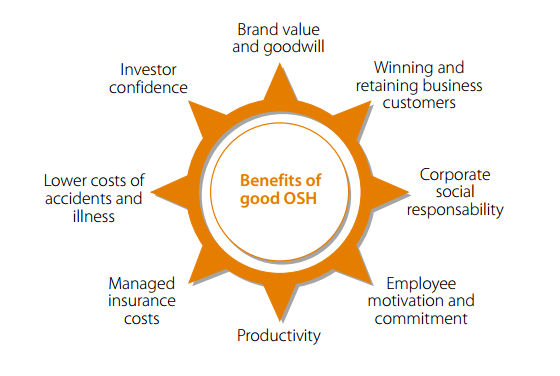

Business benefits

- High staff morale. Employees feel safe and take pride in the excellent reputation

- Staff like going to a safer place to work and have comfort the COO stands behind their decisions, they are showing more pride and commitment to the company.

- Proactive lead indicators such as Near Hits and SBO’s are a daily occurrence, Near Hit and incident reporting have increased significantly

- The principle of safety processes are rolling into other disciplines in the business such as quality and analysing the root cause of machinery breakdowns

- There is a healthier workforce and worker’s competency levels have increased

- The CEO is feeling a lot more at ease as he knows the people in the business are not taking avoidable high risks

- The teams are working more efficiently as they are planning better and working smarter from the system implemented

- The company has a better reputation and are now handpicking their employees instead of taking whoever they could get

- No serious incidents have occurred

- Leadership and commitment are enhanced

- Competent and trained employees in the workplace

- There is efficient measures for risk control, staff are involved in risk assessment programs with continuous monitoring and process reviews

Book a Free Consultation

To request an appointment and free consultation with the GoSafety team, simply complete your details below and we will be in contact to confirm a time and date.

Some of Our Clients

With over 25 years of HSEQ experience, GoSafety Solutions has consulted for a number of established and recognised businesses within the Bay of Plenty. We ensure that all of our clients are comprehensively assessed, before making the ‘right’ recommendations in our strategic health & safety solutions. Any of our clients would be happy to provide a testimonial as to the professionalism of our health and safety systems and consultancy. We look forward to the opportunity to add you to the client list. Call the team today.